oil water separator centrifuge|centrifuge for oil water separation : Brand A purifier is a centrifugal separator for liquid – liquid – solid separation, that separates two liquids of different densities, and a solids, such as water, oil, and fines, from each other. Using a purifier the light liquid phase is typically the .

SH Scientific laboratory and non-medical grade autoclaves are used to sterilize mushroom .

{plog:ftitle_list}

The SteriMega Plus autoclaves are steam sterilization units designed for processing a wide range of materials: solid or porous products and also liquids in pharmaceutical production. The units offer high technical performance and .

A centrifugal water–oil separator, centrifugal oil–water separator or centrifugal liquid–liquid separator is a device designed to separate oil and water by centrifugation. It generally contains a cylindrical container that rotates inside a larger stationary container. The denser liquid, usually water, . See moreA mix of oil and water is pumped constantly into a cone-shaped separating apparatus at an angle, which creates a spinning vortex. The filtration is a result of the force balance that occurs on . See moreThere are other types of separators that use gravitational forces to separate mixtures, but these other types of forces are not as strong as the centrifugal force in . See more• Centrifuge See more

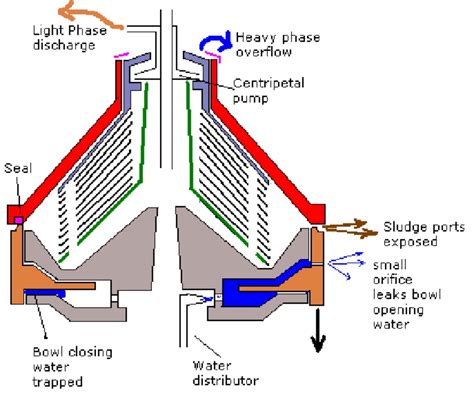

What does a centrifugal oil separator do? The main aim of a centrifugal oil separator is to remove impurities and particulate from the lubrication oil to encourage the engine's high performance and economical operation. Poor lube oil quality may cause increased wear on the crankshaft, camshaft, turbocharger, and other vital parts, and replacement of expensive components may .A purifier is a centrifugal separator for liquid – liquid – solid separation, that separates two liquids of different densities, and a solids, such as water, oil, and fines, from each other. Using a purifier the light liquid phase is typically the .A hydraulic oil centrifuge separates water and fine solids from hydraulic oil continuously. The centrifuge bowl rotates at 7,800 RPM generating 7,000 Gs of force. This centrifugal force is enough to separate particles down to 0.5-micron level and all free water.Discover what centrifugal force is, how centrifugal oil separators make use of it, and what factors play a role in making these systems perform their best. . As the mixture rotates at high speeds, the centrifugal force causes the heavier components (water and solids) to be pushed outward, forming a dense layer along the vessel's walls. .

Separators for food, beverage, biopharma industry, marine applications, oil, gas and more. Centrifugal separator equipment for your application needs. Products; Dairy processing; Food and beverage . % of the world’s fleet rely on Alfa Laval separators for handling traditional and new fuels as well as lube and waste oil, bilge water .The CentraSep® centrifuge is the proven leader in separating all types of solids from liquids. Our unique centrifuge technology assists with oil and water separation systems by helping to remove the solids from the liquid. This allows the high speed liquid-liquid separation system to work at maximum efficiency and speed. Since 1981, CentraSep centrifuges have [.]A centrifugal water–oil separator, centrifugal oil–water separator or centrifugal liquid–liquid separator is a device designed to separate oil and water by centrifugation.It generally contains a cylindrical container that rotates inside a larger stationary container. The denser liquid, usually water, accumulates at the periphery of the rotating container and is collected from the side of .• Free water & solids removing. Advantages: Based on the differences in density between the different matters, COS series oil centrifugal separator is the most efficient way to remove free water( more than 200ppm) and coarse particulates from oil and fuel. Flowchart:

Monitoring of Oil-Water Emulsions: Oil-water emulsions can occur during oil production and transportation, which can complicate separation processes. Centrifuges are used to break down these emulsions and separate oil and water phases effectively. . 10 Considerations When Utilizing Crude Oil Centrifuges. When utilizing crude oil centrifuges .A waste oil centrifuge is a flow-through or continuous separator. The contaminated waste oil enters the centrifuge, and clean oil, water, and sludge are discharged from the centrifuge. This is a concurrent process that does not need the centrifuge stoppage for cleaning. For example, oil-water separator has been integrated with four 1000 bbl storage tanks on a Responder Class Oil Spill Response Vessel (OSRV), which has been deployed in the USA . Separation of oil and water by centrifuge utilizes a dynamic mechanical apparatus to induce an intense pressure gradient and separate oil and water by density.

The Vortex at Work in Centrifugal Oil Water Separator. A Hydrocyclone uses centrifugal forces to separate high-density water and solids from low-density oil and finer solids. The constant flow and spinning vortex in a cone-shaped separator cause the high-density liquid to move to the outside and the lower density fluid and sediment to sit on .

oil centrifuge purification system

MP centrifuges have been designed to eliminate cross contamination between contaminated oil and cleaned oil, from the unique impeller drawing oil in at the base of the units to oil-sealed components. All ensure cleaned oil and dirty oil remain separate. The oil field at Bohai Bay is said to be China's largest offshore oil discovery. Disc stack centrifuge with nozzle bowl for crude oil or produced water separation. Installation of GEA Westfalia Separator centrifuges on board The Hai Yang Shi You 117, FPSO. Manufacture of skid mounted centrifuges, designed for low space, high performance .Oil purifiers usually maintain a layer of water inside the bowl to act as a seal for the oil known as sealing water. Without it, the oil will flow out together with the contaminants. If removal of water is not needed, the centrifuge can be modified so that no water layer is needed.

Centrifugal force is the force that drives the separation of impurities from oil in a centrifuge. It works by spinning a mixture of oil and impurities in a rapidly spinning centrifuge bowl, which causes the heavier contaminants to be forced outward and collected on the centrifuge bowl wall from the purified oil.Hydraulic Centrifugal Oil Water Separator . Description: PDSV series automatic discharging separator is special equipment for oil and fat refining, it has the traits as high rotating speed, operating stability, completely sealed up of the inlet and outlet system, lower noise and fine separating affection. A liquid-liquid centrifuge has been tested for possible application as a downhole method for separating, crude oil from produced water. Centrifugal separators of various sizes (from 2- to 25-cm . An Oily water separator on a ship brings down the oil content of the water that has to be discharged overboard. Find out about the construction and working of ows inside the article. . Centrifuges, however, used to do opposite task- remove water from a larger oil quantity. They also need to remove solid impurities and sludge.

Our best Stainless Steel High Speed Centrifuges - Decanters and Oil Water Separators. Used for 3 phase separation in a vareity of processes including separating and clairifying liquids, plant oils, coconut oil, hemp oil refining, beer and yeast extraction, cell harvesting, chemical processing,separating emulsions, fuel and oil polishing, separation of filterable and non .The heated oil has a much lower viscosity conducive to easier centrifuge separation. The extremely high centrifugal force within the separator bowl slings out the water and sludge from the oil. The centrifugal purifier internally pumps the separated clean fuel oil to a local storage tank, which feeds the turbine or engine.Separators for Marine. Centrifugal separators from GEA specialize in the purification of fuel and lube oil as well as bilge and EGR water treatment on board ships. With their high g-force, the separators reliably guarantee high performance and economic operation of ship engines, and boost their service life even under extreme conditions.The centrifuges that can show the percentage of water and sludge in crude oil are benchtop centrifuges that use test tubes. These centrifuges are also known as benchtop testers or grinders. The crude oil centrifuges we refer to here are large-capacity industrial machines that continuously separate crude oil from water and sludge.

Antagonistically functionalized meshes can simultaneously separate oil and water and show continuous separation flow rates of water (900 L m−2 h−1) and oil (400 L m−2 h−1) with high .The oil centrifuge at 80 PSI generates a centrifugal force of 3017 G?s Removing solids to less than 2 micron. No filters to buy. You can build a filtration system with this unit. The oil centrifuge will filter waste vegetable oil, Waste Motor Oil, hydraulic oil, and ATF that is heated to over 150 F.Oil Water disc separator. Our products are widely used in pharmaceutical, food industry, daily chemical, health industry, sewage recycling, and many other fields. Our Application. Wastewater Treatment. Industrial Centrifuges. Salt Separation. Oil -water centrifuge. Cannabis Oil Extraction. Food & Beverage. Welcome To Reyes Machinery Co.,Limited.

industrial used oil centrifuge

About this page. Comprehensive catalog of Separators, featuring 72 products from 6 Separator manufacturers. View technical specifications, compare products, download datasheets and contact the manufacturer to make sales inquiries.

industrial centrifuge liquid base

crude oil centrifuge machine

To prevent burns, allow unit to cool before cleaning. Wipe with a soft dry cloth and occasionally with a damp cloth and mild soap or detergent. Drain water from reservoir using drain tube .

oil water separator centrifuge|centrifuge for oil water separation